Baby pants diaper are disposable hygiene products designed specifically for babies. They are intended to absorb urine and feces, making them convenient to change and easy to use, essential for modern parents in their childcare routines. The production process of jiayue baby pants diaper is highly automated and precisely controlled, ensuring high quality, comfort, and safety for babies. Below is the detailed production process of jiayue baby pants.

1.Raw Material Preparation: Before production begins, the factory staff prepares the necessary raw materials.

2.Core Flattening And Shearing: The first step in the production process is to flatten and cut the cotton core. Made of absorbent materials, the cotton core is pressed into an even thickness by machines, then cut to size, forming absorbent cores that fit the pull-up pants.

3.Surface Wrapping: The cut cotton cores are fed into a wrapping machine, where non-woven fabric layers are placed on both the top and bottom, enveloping the cores in between.

4.Top Sheet Compound:An additional absorbent top layer material is compounded onto the wrapped layer.

5.Simultaneous:The bottom layer compositing process includes several steps:

①Cartoon Printing: Decorative designs are printed on the bottom non-woven fabric, making the pull-up pants more appealing.

②Wetness Indicator: A wetness indicator material is added to the back sheet, changing color when the pull-up pants are wet, alerting parents to change them.

③Spandex: Spandex is incorporated into the waistband area to enhance elasticity, ensuring the pull-up pants fit snugly around the baby's waist to prevent leaks.

④Glue Adhesion: Glue is used to securely bond the various layers together, ensuring the structural stability of the pull-up pants and preventing them from coming apart.

6.360° Waist bonding: A 360° waistband design is added and adhered to the waistband area. This design provides all-around fit and support, making the pull-up pants nappies more comfortable and leak-proof.

7.Finished Product:The pull-up pants are neatly stacked by a stacking machine to form finished product sheets. They undergo strict quality checks to ensure each pull-up pant meets the standards.

8.Inner and Outer Packaging: The finished product sheets are grouped into specified quantities and packed into inner packaging bags. The outer packaging involves sealing to prevent moisture or contamination.

Jiayue's entire production line is designed for high efficiency, with a maximum production speed of up to 630 pieces per minute. The production process employs fully automated machinery to ensure the high quality and efficiency of the products, guaranteeing stable output. Jiayue has been deeply involved in the hygiene product industry for over 10 years, exporting to more than 70 countries, maintaining a stable supply chain, and offering one-stop services. Currently, Jiayue consistently ships 100*40HQ containers monthly. Jiayue always treats others with sincerity, impresses customers with professionalism, and opens markets with quality. We look forward to further cooperation with you to create a better future together!

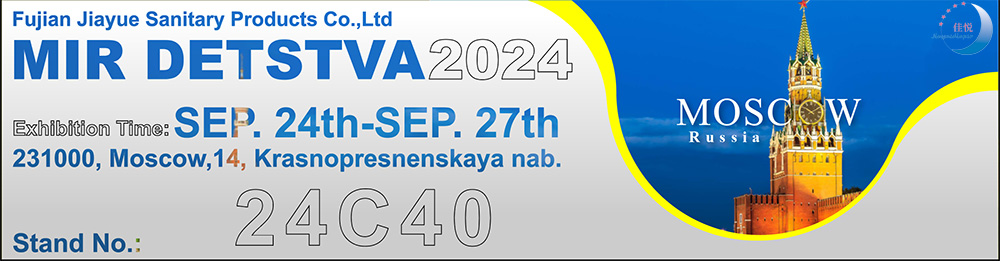

Meanwhile, Jiayue is about to set off again for the exhibition MIR SETSTVA 2024,Russia from September 24th to 27th, and we look forward to meeting you at the show.the exhibition information is as follows:

baby diapers super pants,baby diapers size large men baby pants men,baby diaper pants wholesale,baby diaper pants disposable,pull ups diapers boy,newborn baby diaper pants,pull up diaper girls,cheap pull up diapers,pull on diapers,baby diaper pants high quality